HXSCO - Reliable Aluminum Supplier

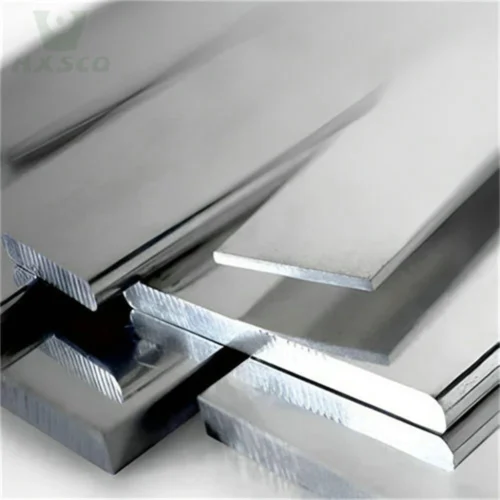

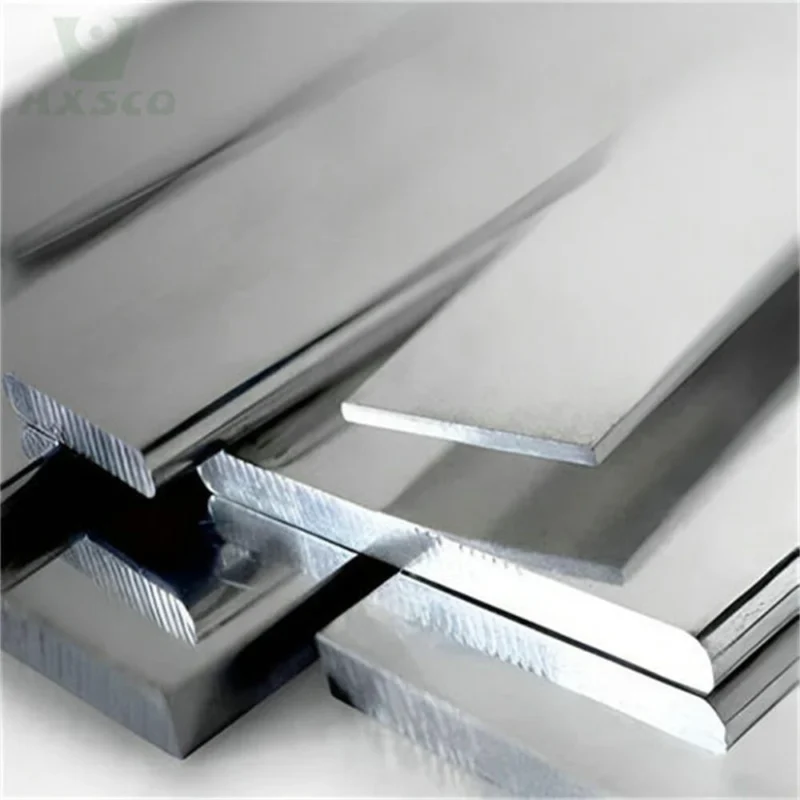

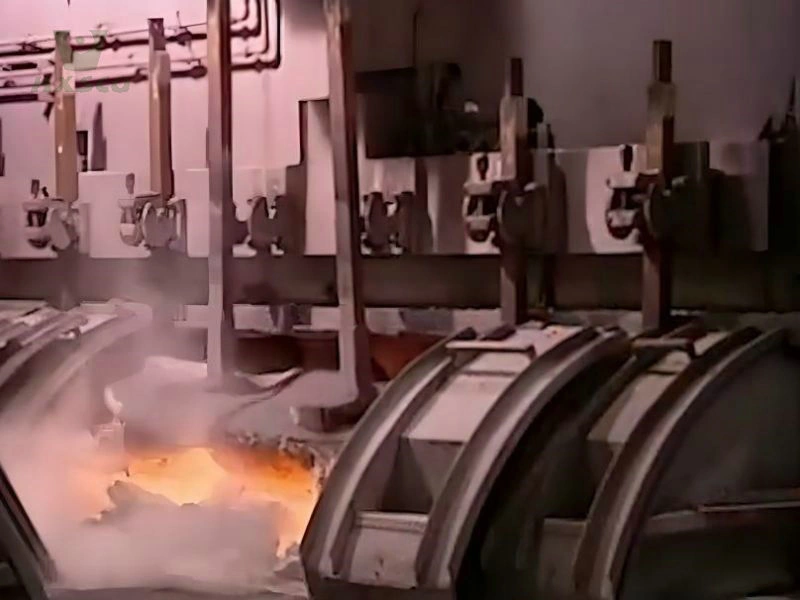

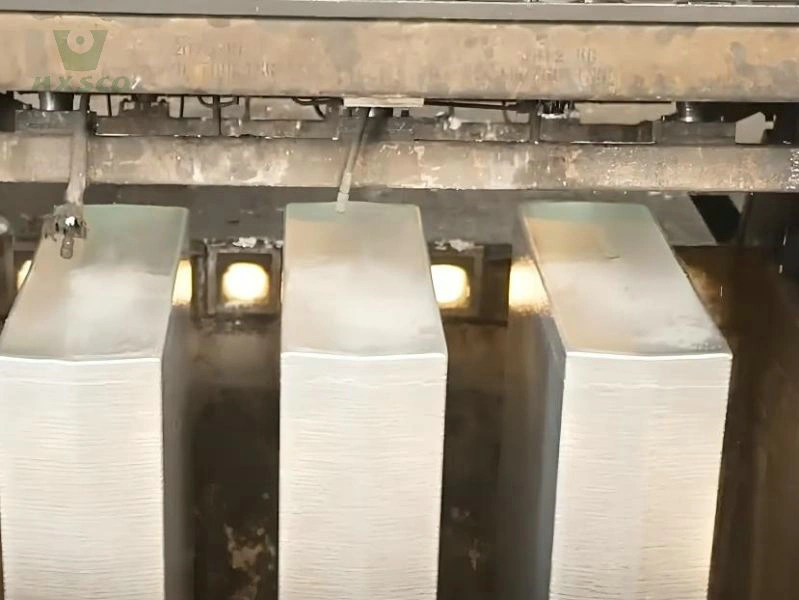

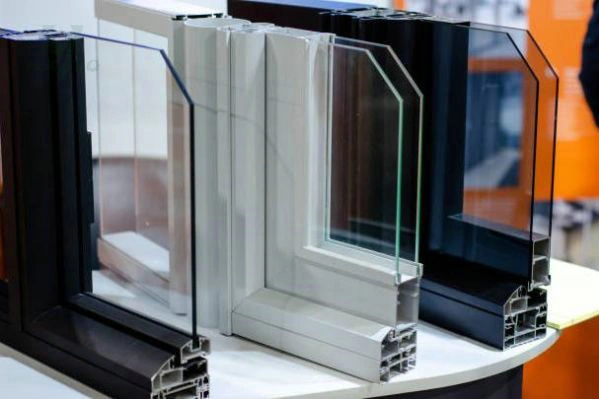

HXSCO is a reputed aluminum supplier and manufacturer in China. The company focuses on providing quality aluminum materials to customers worldwide. HXSCO's aluminum is finely machined for superior quality and performance. Its aluminum has the advantages of high strength, lightweight, corrosion resistance, etc. Our aluminum products are suitable for various industries. Such as construction, automotive, aerospace, and so on.

As an excellent aluminum material supplier, we have a professional sales and technical team. Our team strives to provide wholesale services for aluminum products. HXSCO can provide customers with personalized solutions and comprehensive technical support.

When you choose HXSCO, you will get high-quality aluminum and worry-free supply chain management. We understand that aluminum is critical to your business. So, our commitment is to provide the highest quality products and services to help you achieve business success.